top of page

Adam Adcock

Mixed- Media Sculptor

Process images in a very random order

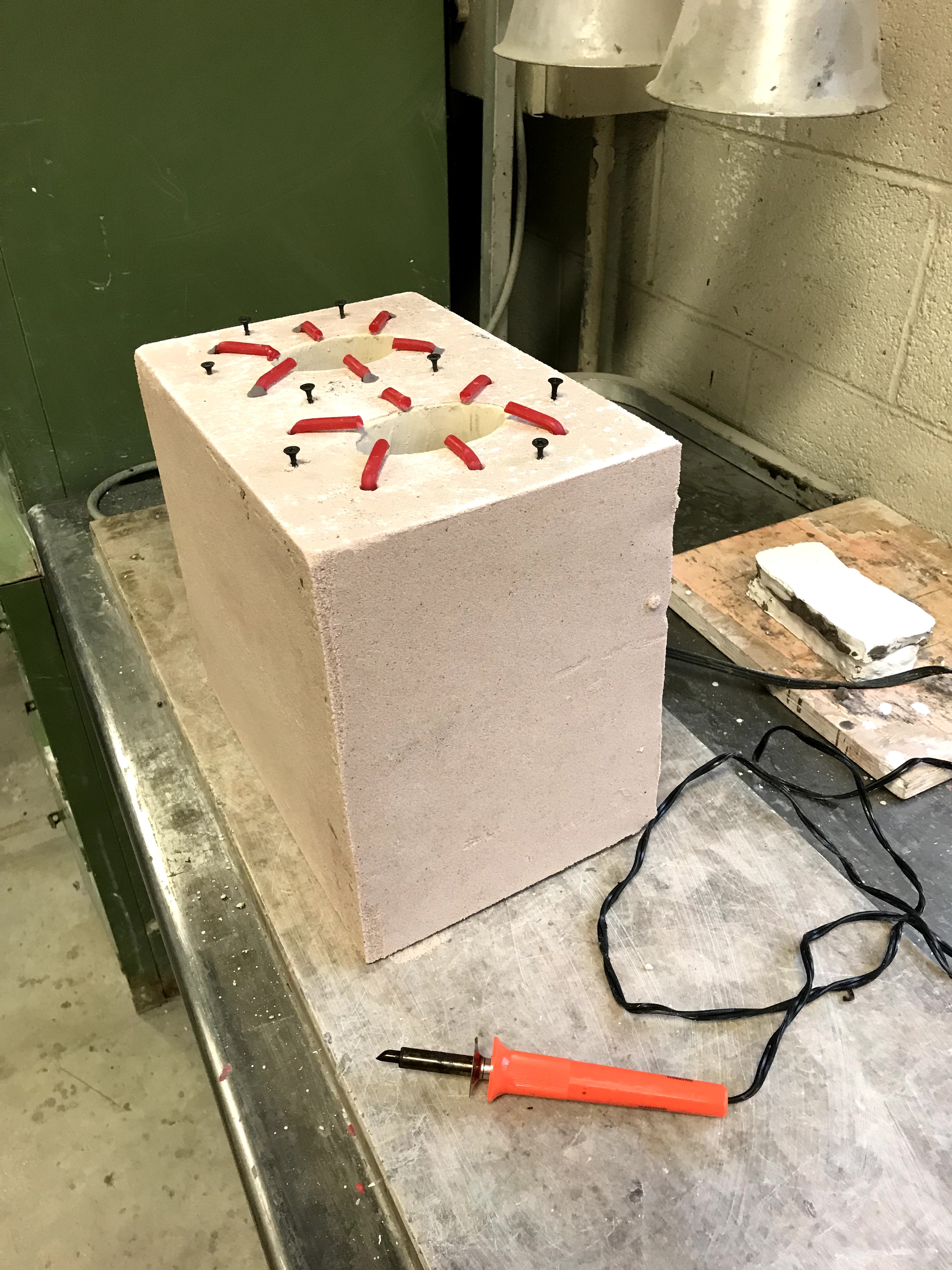

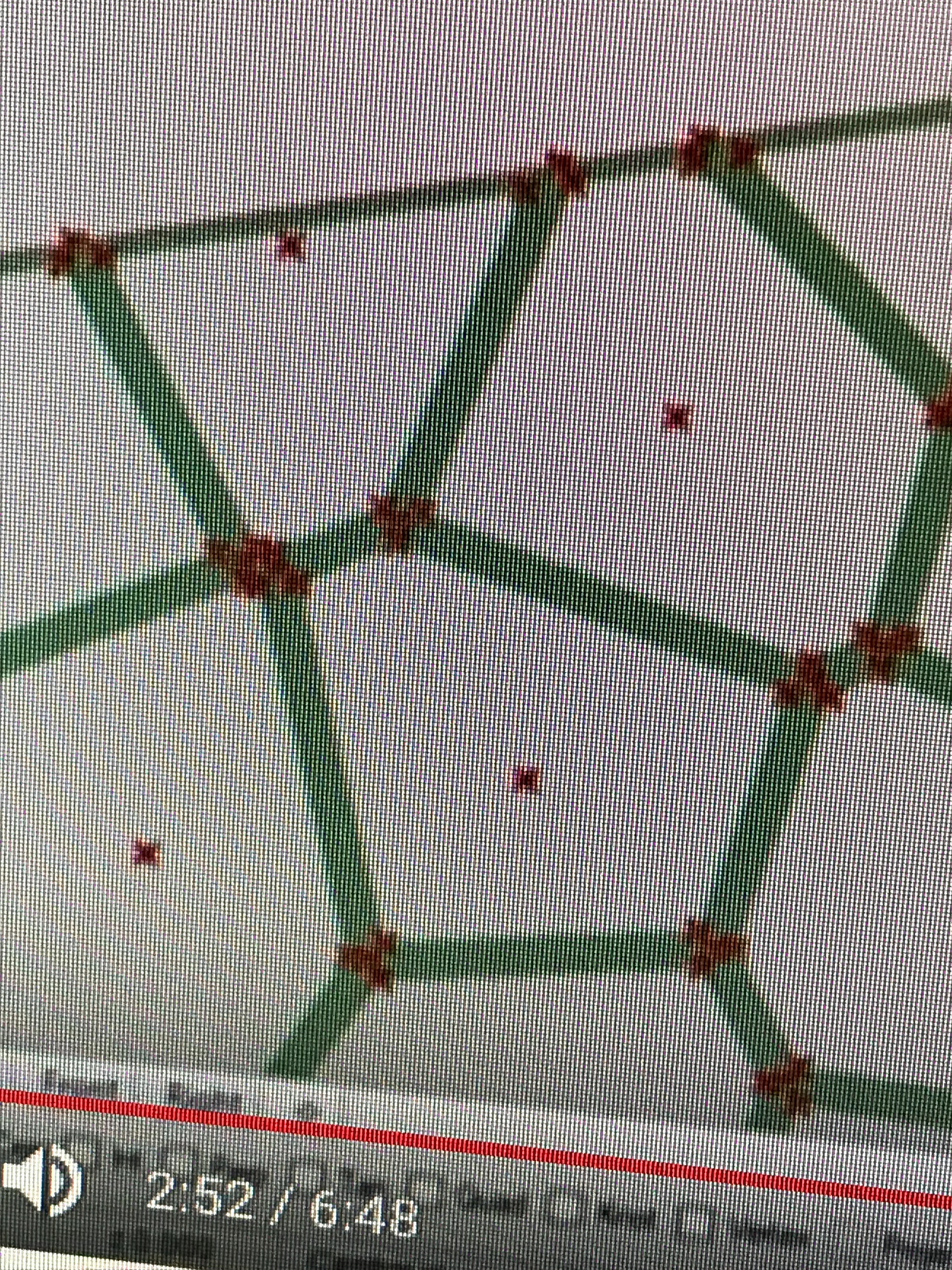

resin bonded sand moldfor WNSC iron pour. Voronoi cup patterns inside. |  cleaning up iron cups |  voronoi pattern on iron cup |

|---|---|---|

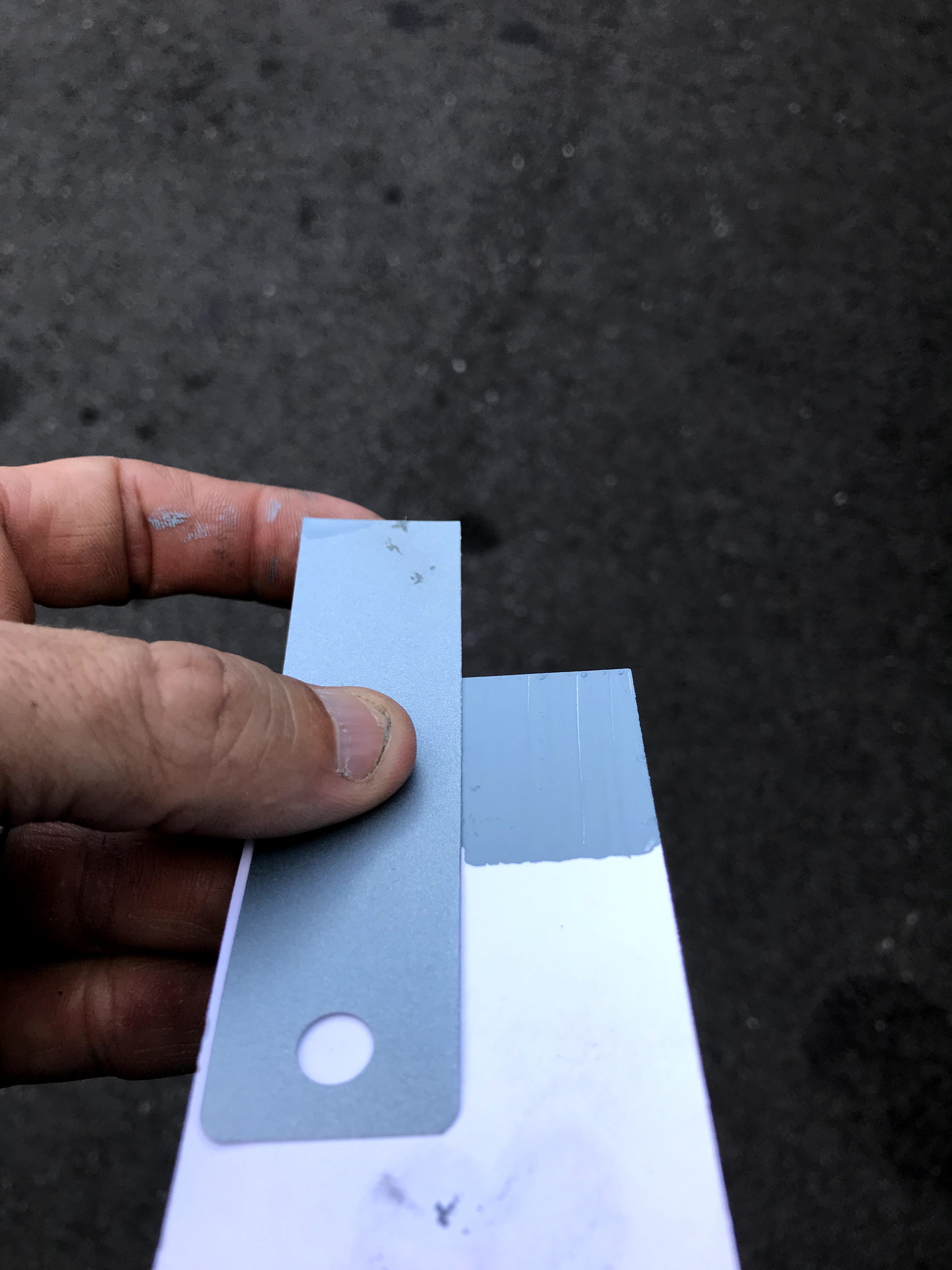

scalloped rim |  aluminum seat platform for kayak |  IMG_2510 |

3d printed water pattern |  rubber mold of 3d print |  wax sprue system for water pattern |

wax sprue systemwhy not make 2?? |  3d printer enclosure |  wood base for water ripple sculpture |

working on connectionsstainless steel form and cast iron water pattern |  fabricating mailbox |  sketch ideas for commission |

sketch ideas for commission |  oops! while delivering art |  mailbox upright |

patterns for Asheville commission |  beginning of baseAsheville Commission beginning phases |  Rhino Rendering of commission |

working underneath base |  lots of hidden support in base |  putting the pieces togetherAsheville Commission beginning stages |

starting to feel good about this |  Parts coming togetherAsheville commission |  getting angles rightRhino digital rendering |

interior supportsAsheville commission |  selecting stoneAsheville commission |  pattern for concrete pad |

orienting pattern for concrete pad |  scoring and cutting stone |  layering up the stonesEach piece weighs about 350 lbs! |

holding my breath!while trying to glue and flip |  flattening the surfacesand scoring for glue up |  base in progress |

Large circle in process |  fitting pieces together |  glue up is complete |

grinding and cleaning up seams |  Rhino cup designs |  Large circle right after powdercoat |

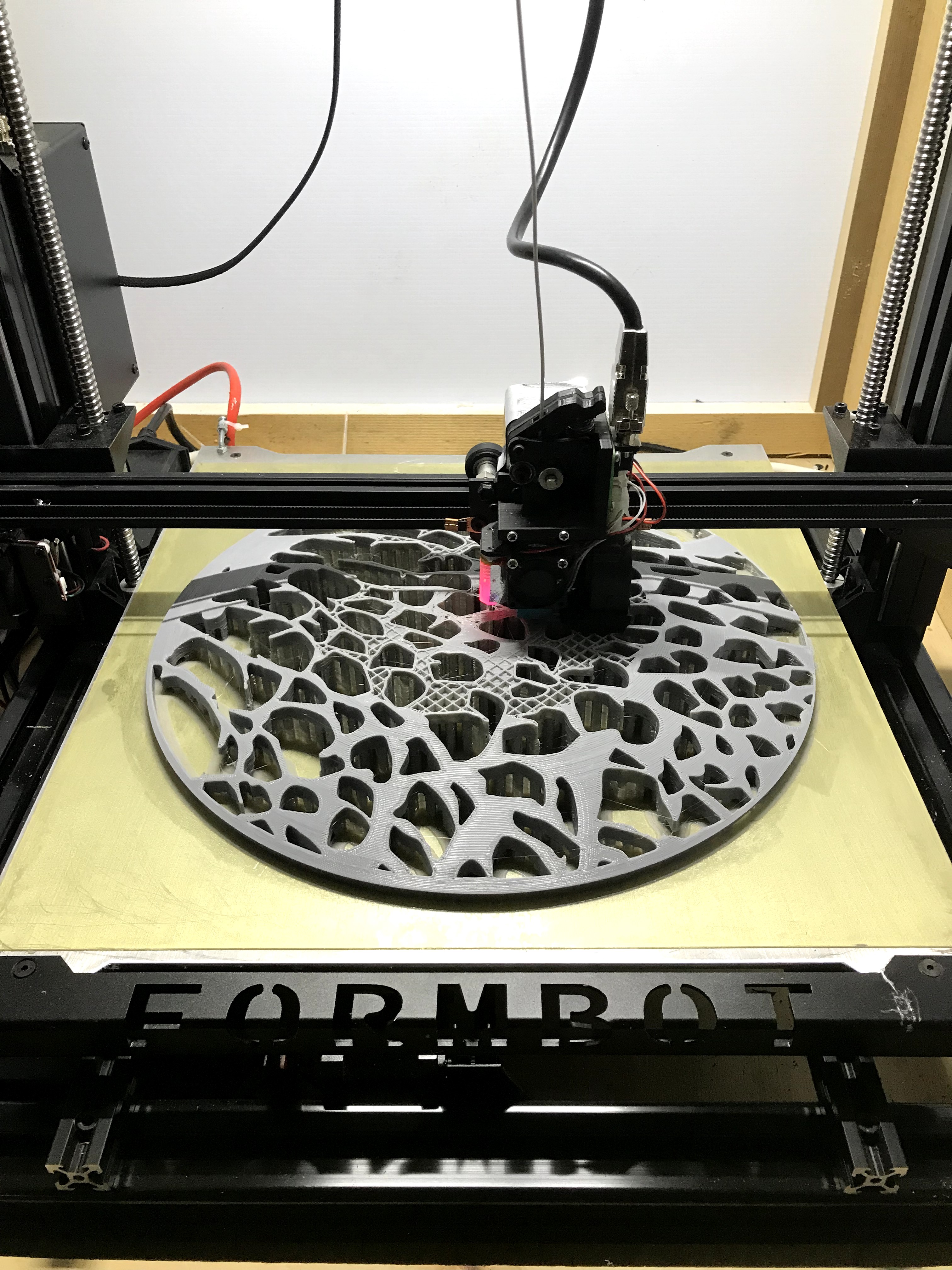

voronoi patterns |  choosing colors for inner circle |  trying to dry out acrylic mortar |

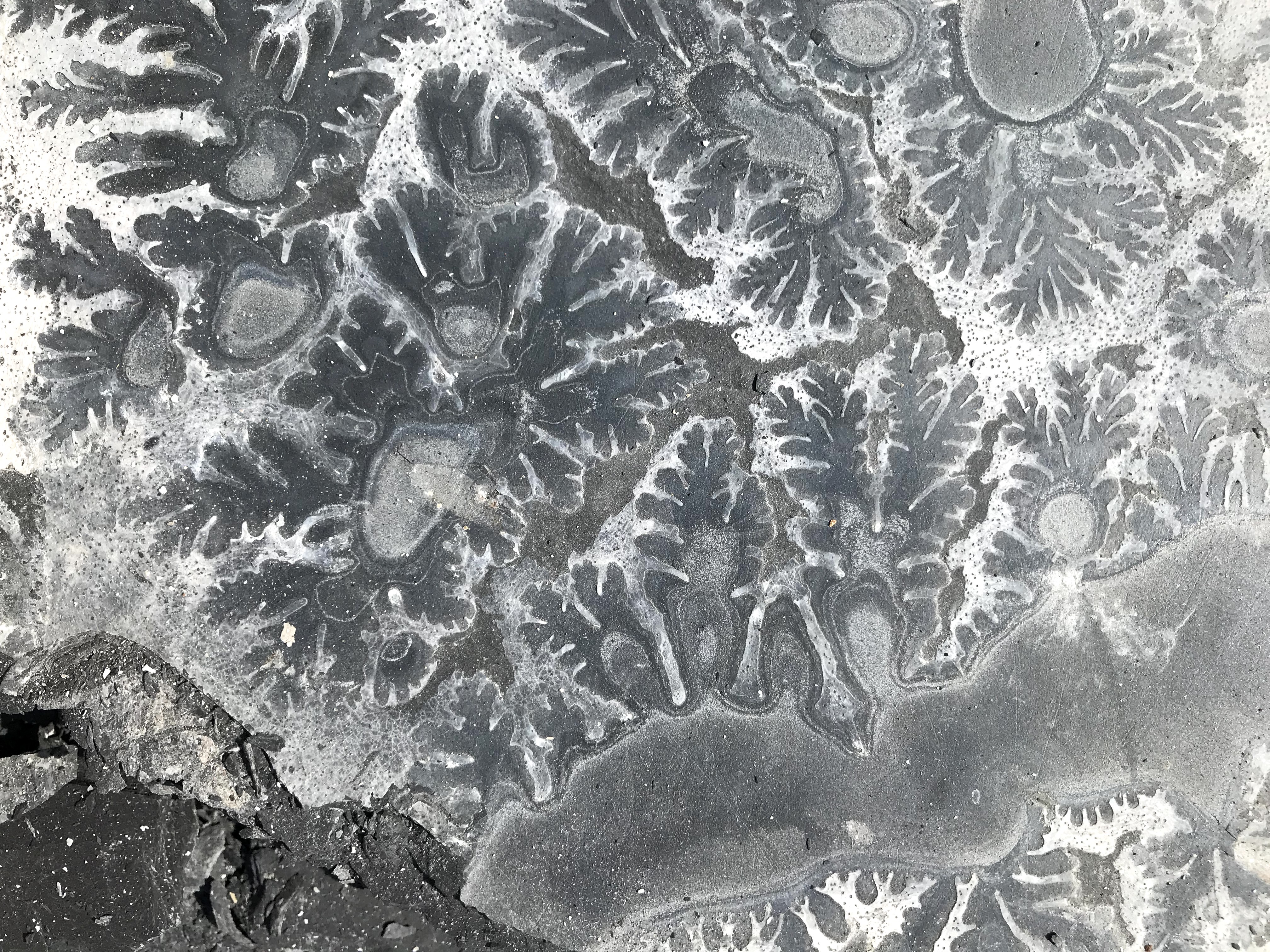

prepping for mortar of stones |  amazing patterns between the layers |  stones ready to ride! |

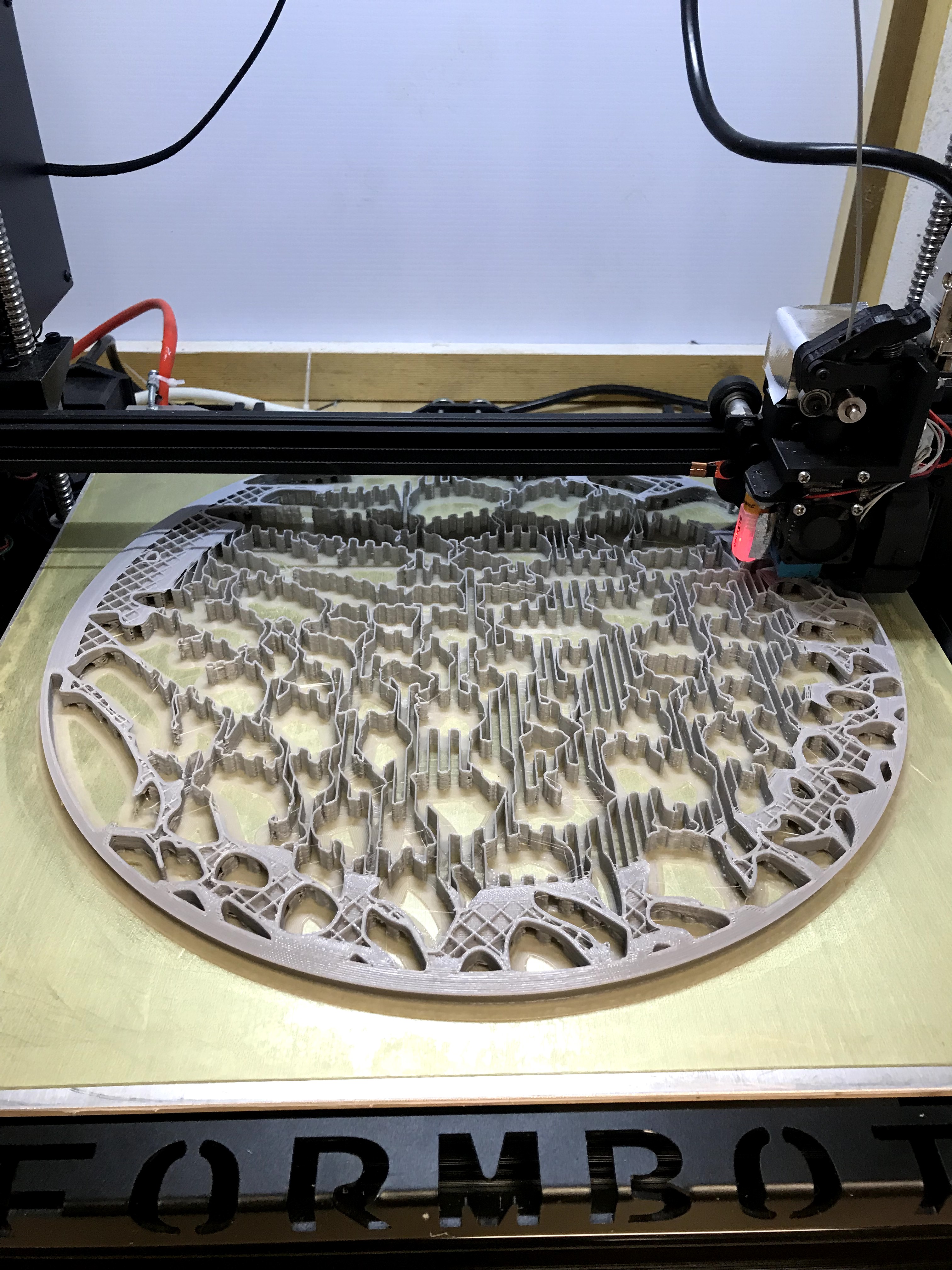

Big circles ready to ride! |  laser cut pattern for mold resist |  3d print in process |

Ready for installleaving ASU! |  3d print further along |  rubber mold time |

rubber mold fail!Didn't use shellac sealer. |  creative solution for wax ventsblind vents drilled into sand. Top of sand mold about to be rammed into place. |

bottom of page